Centro CSSD

Departamento de Suministros Estériles Centrales

Explora el portafolio completo de soluciones CSSD de WEGO—desde envolturas y contenedores de esterilización hasta indicadores de seguimiento y accesorios para lavadoras—diseñados para apoyar flujos de trabajo de reprocesamiento confiables y mejorar la seguridad del paciente.

WEGO Medical WEGO está comprometido en desarrollar, fabricar y suministrar un sistema de solución CSSD de alta calidad, seguro y confiable que mejore el control de infecciones, optimice procesos y productividad, mientras minimiza costos.

A través de nuestra vasta experiencia en el diseño de desinfección y esterilización y tecnología de vanguardia, nuestro mayor objetivo es desarrollar soluciones de alta calidad para prevenir infecciones y contaminación cruzada en instalaciones de atención médica.

Como un famoso proveedor de soluciones de control de infecciones, WEGO es una empresa líder y pionera en el diseño y fabricación de Esterilizadores de Vapor,

Esterilizadores de Plasma a Baja Temperatura, Lavadoras-desinfectadoras, Gabinetes de Secado Médico, Lavadoras Ultrasónicas, sistemas de tratamiento de agua, logística de CSSD &

sistema de almacenamiento y Accesorios, Consumibles y Material de Embalaje, etc.

ÁREA LIMPIA

Los artículos son retirados de la limpieza y desinfección y entran en el área limpia, donde son seguros para ser manipulados y listos para ser almacenados, inspeccionados, empaquetados y luego colocados en el esterilizador de plasma a baja temperatura o esterilizador de vapor a alta presión según las características de los artículos.

Área Avanzada de Productos Sucios

El Área de Productos Sucios es donde comienza el primer paso del control de infecciones. Los instrumentos contaminados de las salas de operaciones y salas son manipulados con precisión utilizando estaciones de trabajo de limpieza manual para tareas delicadas, lavadoras ultrasónicas para instrumentos de lumen fino, y lavadoras-desinfectadoras ultrasónicas de vacío para dispositivos complejos. Volúmenes más grandes son procesados de manera eficiente a través de lavadoras-desinfectadoras automáticas, apoyadas por un dedicado sistema de tratamiento de agua para garantizar una calidad de limpieza consistente. Finalmente, armarios de secado médico aseguran que cada instrumento salga de esta área seco, seguro y listo para un procesamiento adicional.

- Ver el Sistema de Área de Bienes Sucios>>

Área estéril confiable

El Área Estéril representa la última salvaguarda antes de que los instrumentos regresen a su uso clínico. Después de la esterilización en esterilizadores de vapor a presión avanzada, los artículos se gestionan de manera segura dentro de sistemas de almacenamiento estéril que protegen su integridad hasta su uso. La distribución se realiza de manera segura y eficiente con carros logísticos, mientras que una gama completa de consumibles y accesorios—desde máquinas de sellado hasta herramientas de monitoreo de esterilización—apoya una operación fluida. El escaneo en tiempo real y el seguimiento de inventario garantizan que cada suministro estéril sea confiable, rastreable y fácilmente disponible para el cuidado del paciente.

- Ver el Sistema de Área de Bienes Estériles>>

Área de Limpieza y Desinfección Eficiente

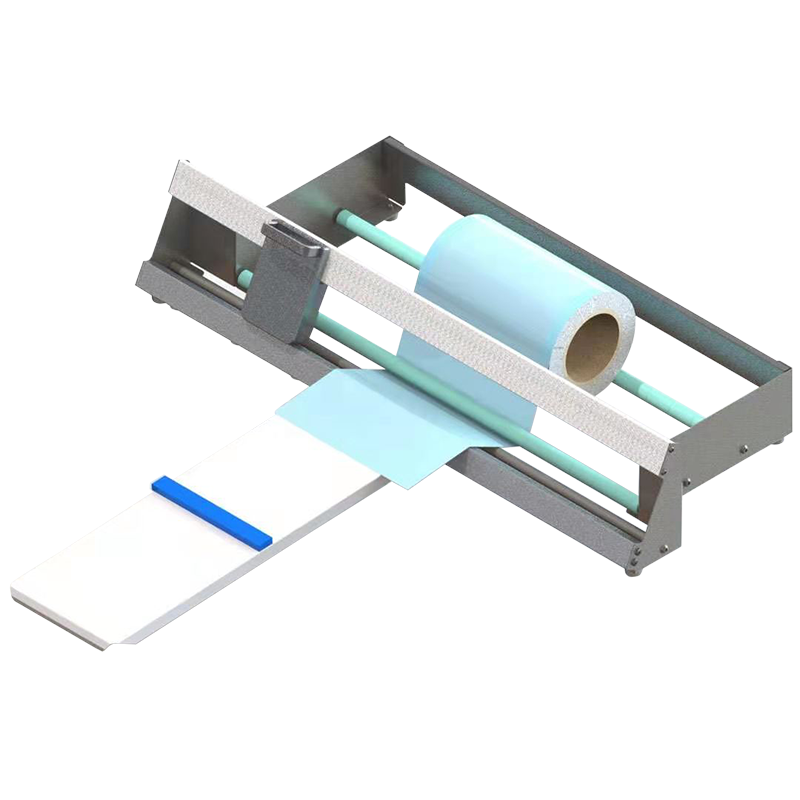

El Área de Limpieza y Desinfección ofrece un entorno controlado donde los instrumentos son secados, inspeccionados, ensamblados y empaquetados con cuidado. Los armarios de secado médico crean condiciones óptimas para un manejo seguro, mientras que los sistemas de empaquetado automatizados y las soluciones de etiquetado con código de barras agilizan el flujo de trabajo y mejoran la trazabilidad. Una vez listos, los instrumentos se mueven sin problemas a esterilizadores de plasma a baja temperatura para dispositivos sensibles al calor o esterilizadores de vapor a alta presión para herramientas quirúrgicas estándar. Este proceso integrado asegura una preparación de esterilización completa, minimiza los riesgos de contaminación cruzada y apoya los más altos estándares de seguridad hospitalaria.

- Ver el Sistema de Área de Bienes de Limpieza y Desinfección Eficiente>>

Soporte integral del equipo global WEGO

Cuando te asocias con WEGO, obtienes más que productos médicos de confianza: obtienes la fuerza del equipo de soporte global WEGO. Estamos dedicados a ayudarte a maximizar el rendimiento, garantizar la confiabilidad y ofrecer mejores resultados para los pacientes en todo el mundo.

Con 37 años de experiencia, fabricación avanzada y una red de servicios mundial, WEGO proporciona asistencia oportuna, orientación técnica y soluciones personalizadas. Nuestro equipo trabaja codo a codo contigo para mantener las operaciones funcionando sin problemas y de manera eficiente.

En WEGO, nuestro compromiso comienza antes de la primera entrega y crece a lo largo de nuestro viaje juntos. Su éxito impulsa nuestra misión, y su confianza alimenta nuestro progreso.

- Acceder a WEGO Expert Support >>

P1. ¿Cuál es el papel del CSSD en un hospital?

R: El Departamento Central de Suministro Estéril (CSSD) es responsable de limpiar, desinfectar, esterilizar, almacenar y distribuir instrumentos médicos. Asegura el control de infecciones, la seguridad del paciente y la eficiencia del flujo de trabajo en todos los departamentos clínicos.

P2. ¿Por qué es crítico el tratamiento del agua en el CSSD?

R: La calidad adecuada del agua (agua blanda o agua RO/DI) previene la acumulación de sarro, reduce las manchas en los instrumentos, mejora la consistencia de la limpieza y prolonga la vida útil del equipo, asegurando el cumplimiento de los estándares internacionales.

Q3. ¿Cómo elegir entre la esterilización por plasma y la esterilización por vapor?

A: Se recomienda la esterilización por plasma para artículos sensibles al calor y la humedad, ofreciendo ciclos rápidos a baja temperatura con residuos mínimos. La esterilización por vapor es adecuada para instrumentos robustos que pueden soportar alta temperatura y presión, asegurando una esterilización de amplio espectro.

Q4. ¿Qué accesorios y consumibles se requieren para las operaciones diarias del CSSD?

A: Los elementos esenciales incluyen cestas de lavado, bandejas de instrumentos, máquinas de sellado, indicadores químicos y biológicos, materiales de embalaje, carros de transporte y sistemas de etiquetado. Estos aseguran un flujo de trabajo fluido y el monitoreo de la calidad de la esterilización.

Q5. ¿Cómo se logra la trazabilidad en el CSSD?

A: La trazabilidad se gestiona a través del escaneo de códigos de barras o el seguimiento por RFID en cada paso (recepción, limpieza, embalaje, esterilización, almacenamiento, distribución). Esto crea un registro digital completo para el cumplimiento, retiradas y aseguramiento de la calidad.