CSSD Center

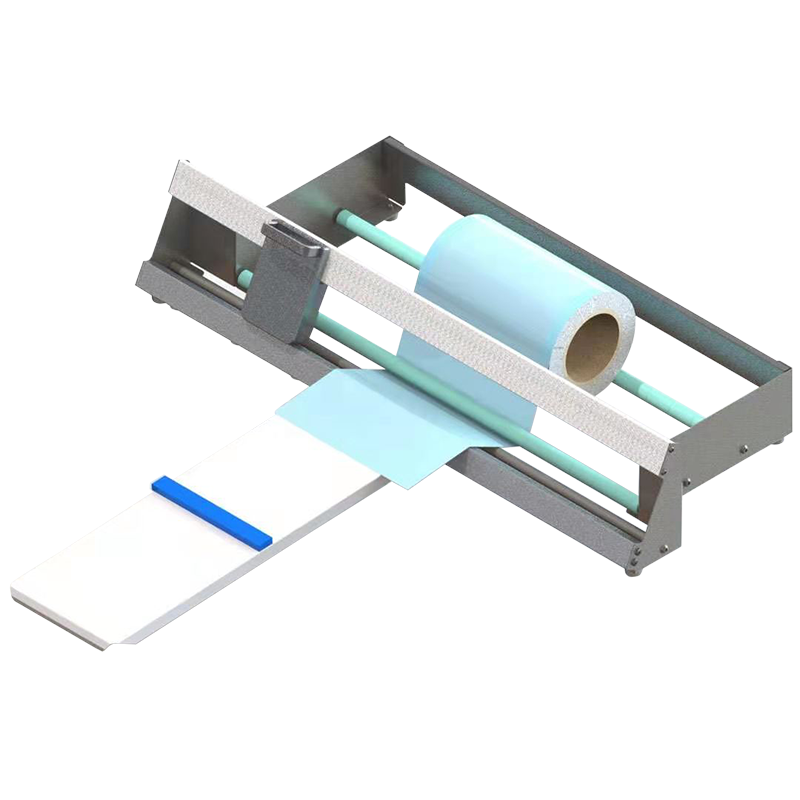

SOILED GOODS AREA

Explore WEGO’s full portfolio of CSSD solutions—from sterilization wraps and containers to tracking indicators and washer accessories—engineered to support reliable reprocessing workflows and enhance patient safety.

WEGO is committed in developing, manufacturing and supplying high quality, safe and reliable CSSD solution system that improve infection control, optimize processes and productivity, while minimizing costs.

The Reliable Sterile Area ensures hospital staff consistent access to fully sterilized instrument sets without the need for reprocessing or last-minute checks. Controlled temperature, humidity, and positive-pressure airflow prevent moisture, dust, and contamination, reducing rework and supporting on-time surgical schedules. Learn more about our CSSD solutions for optimized sterile workflows.

Structured shelving and dedicated sterile storage protect instruments and packaging, simplify organization, speed up retrieval, and minimize shortages. This improves workflow efficiency, lowers costs and workload, and allows staff to focus on high-value clinical tasks instead of corrective reprocessing.

Sistema de tratamiento de agua

Reliable Sterile Area

The Reliable Sterile Area is the final and most controlled stage of the reprocessing workflow, ensuring that every instrument maintains its sterility and structural integrity after completing validated cycles in the steam sterilizers. Once sterilization is finished, packaged instruments enter a dedicated environment where temperature, humidity, and airflow are carefully regulated to prevent moisture, dust, or secondary contamination. Within this space, standardized shelving layouts and protected placement inside sterile storage cabinets help maintain sterility throughout the storage period. Positive-pressure design, clean zoning, and defined movement pathways further reduce the risk of compromise, ensuring that every sterile package remains secure, traceable, and ready for timely distribution to clinical departments.

- View the Sterile Goods Area System>>

Soporte integral del equipo global WEGO

Cuando te asocias con WEGO, obtienes más que productos médicos de confianza: obtienes la fuerza del equipo de soporte global WEGO. Estamos dedicados a ayudarte a maximizar el rendimiento, garantizar la confiabilidad y ofrecer mejores resultados para los pacientes en todo el mundo.

Con 37 años de experiencia, fabricación avanzada y una red de servicios mundial, WEGO proporciona asistencia oportuna, orientación técnica y soluciones personalizadas. Nuestro equipo trabaja codo a codo contigo para mantener las operaciones funcionando sin problemas y de manera eficiente.

En WEGO, nuestro compromiso comienza antes de la primera entrega y crece a lo largo de nuestro viaje juntos. Su éxito impulsa nuestra misión, y su confianza alimenta nuestro progreso.

- Acceder a WEGO Expert Support >>

Q1. What environmental conditions are required to maintain sterility in the Reliable Sterile Area?

A: Temperature, humidity, and positive-pressure airflow must remain within controlled ranges recommended by international guidelines to prevent moisture absorption, dust ingress, and microbial contamination of sterile packages.

Q2. How is the integrity of sterile packaging maintained during storage?

A: Validated sterile packaging materials, proper shelf spacing, and protection from compression, puncture, or excessive handling ensure the sterility maintenance of each pack throughout its storage life.

Q3. What shelving and storage systems are recommended for sterile items?

A: Open or closed sterile storage cabinets, corrosion-resistant shelving, and adjustable modular racks are preferred to maintain airflow, reduce dust accumulation, and protect sterile packs from physical damage.

Q4. What standards and regulatory frameworks do WEGO’s CSSD solutions comply with?

A: WEGO’s CSSD equipment and workflows comply with international standards such as ISO 15883 for washer-disinfectors, ISO 17665 for moist heat sterilization, EN 13060/285 for steam sterilizers, and relevant ISO/CE requirements for material compatibility, bioburden control, and process validation. Compliance ensures consistency, traceability, and global interoperability with hospital infection control systems.

Q5. What factors determine whether instruments should undergo steam sterilization or low-temperature sterilization?

A: Selection depends on material compatibility, heat sensitivity, moisture tolerance, and manufacturer IFU requirements. Stainless steel and most general surgical instruments are steam-compatible, while optical devices, plastic polymers, electronics, and heat-sensitive materials typically require low-temperature plasma sterilization.