Wholesale Medical Consumables

Drug & Medication Delivery Solutions

Discover WEGO’s full range of sterile drug and medication delivery devices engineered to support safe, accurate, and efficient administration across diverse clinical treatments.

WEGO Medical delivers a comprehensive range of drug and medication delivery solutions designed to support accurate dosing, safe administration, and reliable clinical performance across hospitals and outpatient environments. Leveraging decades of manufacturing expertise in sterile disposables, WEGO ensures that each device—from injection and infusion sets to medication transfer and mixing systems—meets stringent global standards for biocompatibility, precision control and contamination prevention.

Built under ISO-certified cleanroom environments, all products undergo rigorous quality inspections to minimize initial bioburden and ensure consistent sterility. These solutions are widely used in anesthesia, oncology, critical care, emergency medicine, and routine ward nursing, offering healthcare professionals stable, efficient, and dependable tools for daily medication management.

Sterile Production

Every product is manufactured within ISO Class 8 cleanrooms equipped with constant temperature and humidity control, as well as real-time monitoring of airborne particulates and microbial loads. These stringent environmental conditions minimize initial bioburden and maintain packaging integrity, providing superior sterility assurance throughout transportation, storage, and point-of-care use.

Clinical Compatibility

WEGO devices are designed to integrate seamlessly with standard infusion pumps, universal Luer-lock connections, medication vials, and drug preparation or reconstitution accessories used across global healthcare systems. This broad compatibility supports efficient medication workflows in departments such as anesthesia, critical care, oncology, emergency medicine, and general nursing.

Reliable Supply Chain

Supported by a global logistics network and stable manufacturing capacity, WEGO ensures continuous product availability for hospitals and distributors worldwide. Efficient planning, fast delivery response, and dependable inventory support help clinical partners maintain smooth operations without interruption.

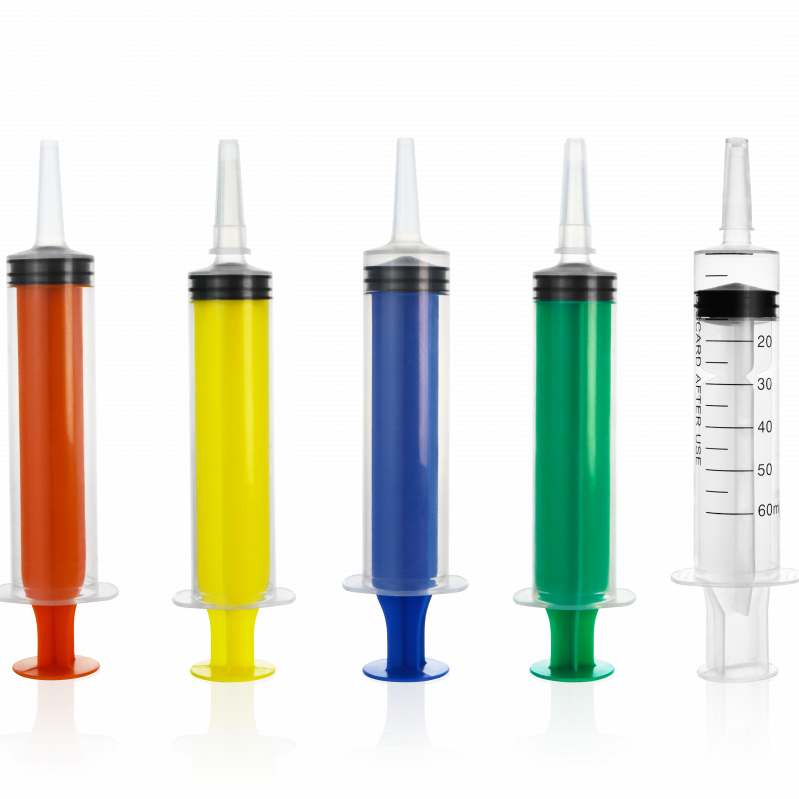

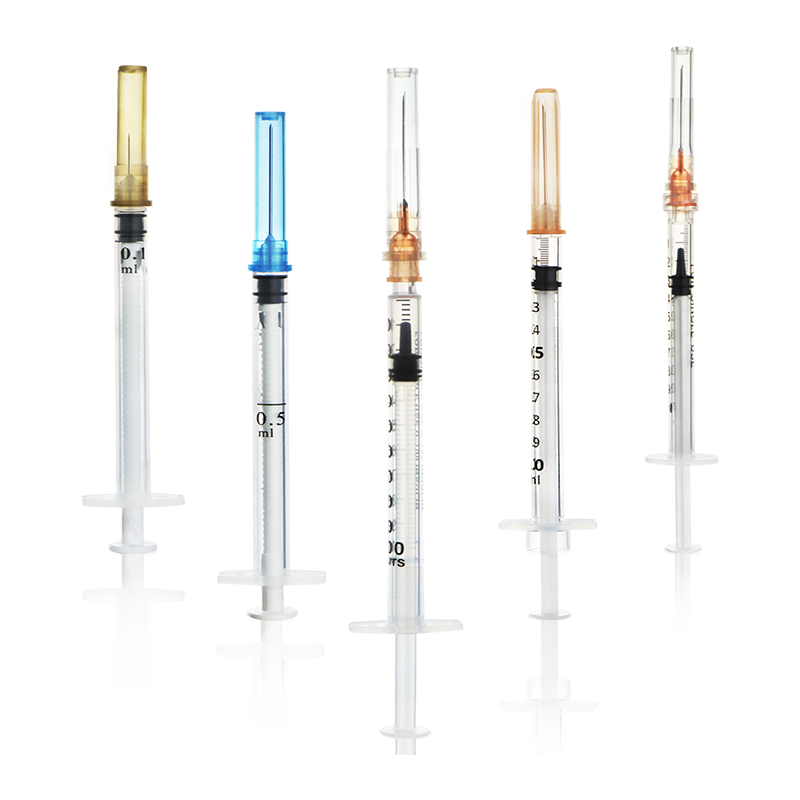

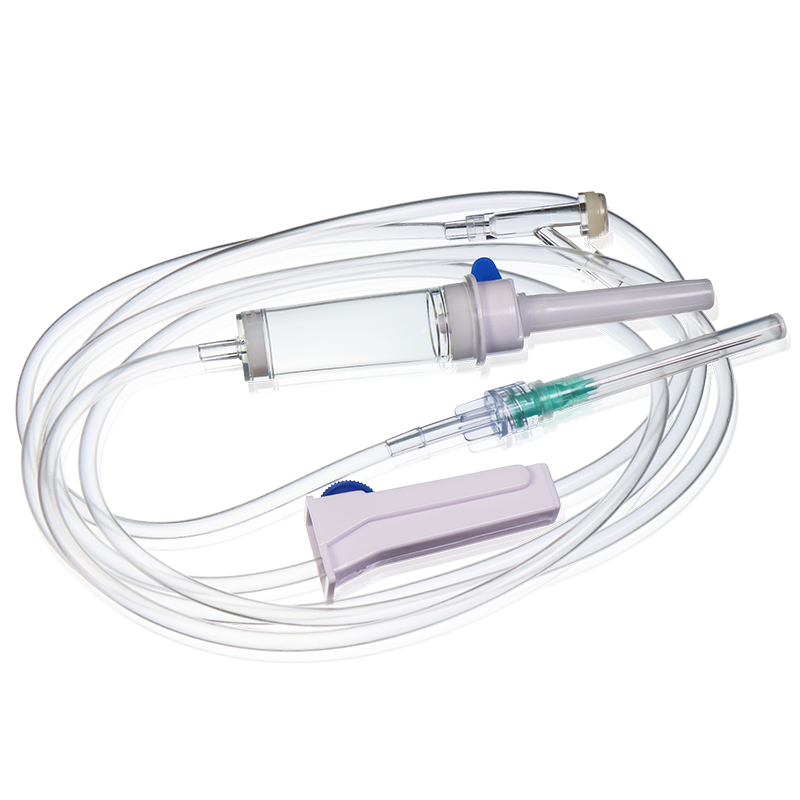

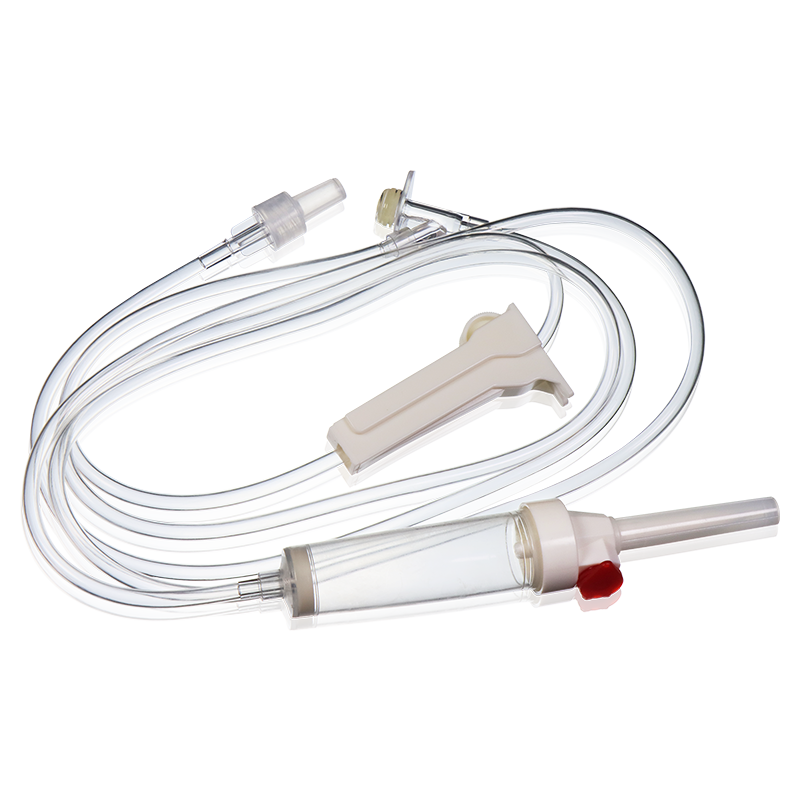

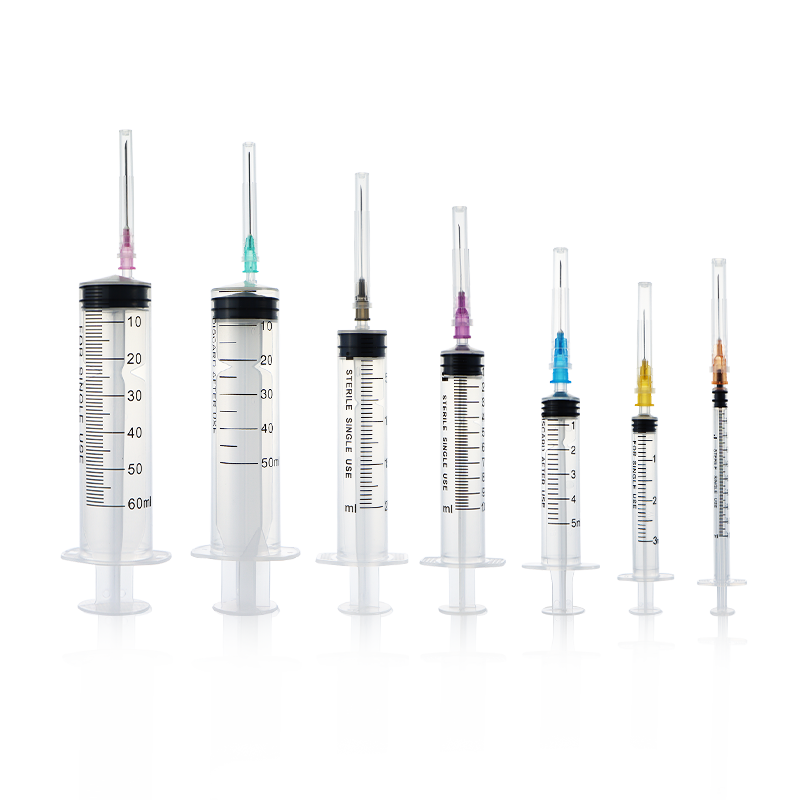

Drug & Medication Delivery

The medication delivery system encompasses the full set of devices involved in preparing, transferring, and administering drugs throughout patient care. From injections and infusions to drug mixing, flushing, and line maintenance, these systems ensure medications are delivered safely, accurately, and in the correct form. A well-designed delivery workflow reduces dosing errors, prevents contamination, and improves efficiency across nursing, anesthesia, critical care, oncology, and emergency departments—directly influencing treatment quality and patient outcomes.

How WEGO Strengthens Medication Delivery

WEGO enhances medication delivery through precision-engineered components and sterile manufacturing in ISO Class 8 environments. Our portfolio—including advanced syringe solutions, dependable infusion set configurations, and devices designed for seamless integration with hospital syringe pump and infusion pump systems—supports stable flow control, accurate dosing, and consistent performance across clinical applications. With optimized materials, validated sterility assurance, and rigorous quality monitoring, WEGO provides an interoperable, evidence-based delivery pathway that maintains accuracy from preparation to final administration and supports uninterrupted clinical workflows worldwide.

| Drug Medication Delivery Consumables | Brochures | Download |

| WEGO Medical Introduction | Brochures | Download |

| WEGO Medical Product Catalog | Brochures | Download |

Q1. What is a medication delivery system in clinical practice?

A: The medication delivery system refers to the integrated process and device ecosystem used to prepare, transfer, and administer medications safely and accurately. It includes core devices such as syringe, infusion set, syringe pump, and infusion pump, ensuring controlled dosing, fluid-path sterility, and predictable administration rates across various clinical conditions.

Q2. Why is device standardization important for medication pathways?

A: Standardizing syringes, infusion sets, and pump-compatible components reduces variability in dose delivery, mitigates the risk of misconnections, and ensures interoperability with infusion technologies. This standardization also improves workflow efficiency by providing predictable performance for rate-controlled infusions and bolus dosing.

Q3. How do medication delivery systems help reduce contamination risk?

A: A high-quality delivery system maintains a closed or protected fluid pathway from preparation to administration. Aseptic manufacturing, validated sterilization, and low-particulate materials help prevent microbial ingress and reduce medication reprocessing errors. Proper compatibility between syringe devices and syringe pump mechanisms also prevents accidental backflow or leakage.

Q4. What factors affect the accuracy and stability of medication administration?

A: Key influencing factors include:

- Tolerance and precision of the syringe barrel and plunger

- Flow-regulating design of the infusion set

- Mechanical accuracy of syringe pump and infusion pump drive systems

- Temperature and viscosity of the medication

- Tubing compliance, back-pressure, and pump–device compatibility

- High-precision devices minimize rate deviation and help maintain therapeutic consistency.

Q5. What benefits does an integrated delivery pathway bring to hospitals?

A: An integrated system that aligns syringes, infusion sets, and pump-driven devices provides:

- Safer and more predictable dose administration

- Reduced medication waste

- Better alignment with clinical protocols

- Improved traceability and regulatory compliance

- Lower device failure rates and fewer therapy interruptions