CSSD Center

Medical Autoclave Sterilizer

Discover WEGO’s medical autoclave sterilizer systems engineered to deliver consistent, validated, and repeatable sterilization across hospitals, CSSD departments, dental clinics, and laboratory environments. Designed to meet strict medical standards, WEGO autoclaves support effective infection control, workflow efficiency, and long-term operational reliability.

WEGO medical autoclave sterilizers are developed to support the full spectrum of clinical and laboratory sterilization needs, from centralized CSSD operations to point-of-care and research environments. Utilizing saturated steam and low-temperature sterilization technologies, WEGO systems ensure effective microbial inactivation while maintaining material integrity and process stability.

Built around capacity flexibility, cycle reliability, and workflow compatibility, WEGO autoclaves enable healthcare facilities to standardize sterilization processes, improve traceability, and maintain compliance with infection prevention protocols across diverse applications.

The sterilization systems are developed to address the diverse sterilization demands of modern healthcare institutions, including operating rooms, dental clinics, central sterile services departments (CSSD), and medical laboratories. By combining steam sterilization and low-temperature plasma technologies, WEGO supports the safe reprocessing of surgical instruments, dental tools, laboratory glassware, reusable medical devices, and heat-sensitive equipment.

Our sterilization portfolio is designed around workflow compatibility, chamber flexibility, and process stability—ensuring effective microbial inactivation while protecting instrument integrity. Whether for high-throughput hospital sterilization, point-of-care dental practices, or controlled laboratory sterilization environments, WEGO systems enable standardized, traceable, and reproducible sterilization performance.

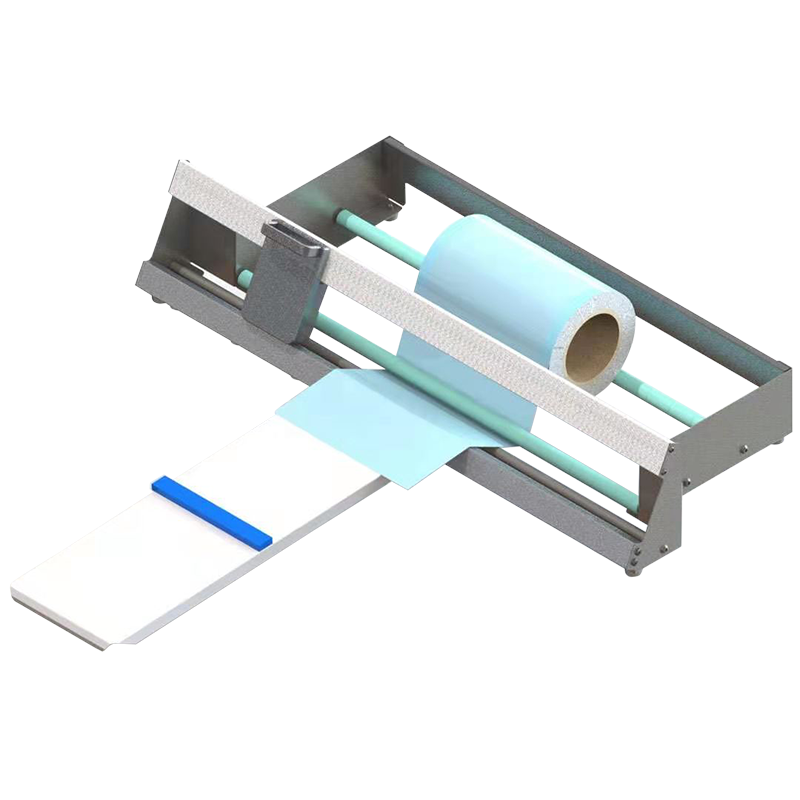

WEGO MSL series vertical pressure steam sterilizer is designed for reliable high-temperature steam sterilization of surgical instruments, laboratory glassware, culture media, and reusable medical materials. Widely applied in research laboratories, medical centers, and clinical support departments, the system provides stable pressure and temperature control to support validated sterilization cycles and consistent microbial inactivation.

Reliable Sterile Area

Medical autoclave sterilizers play a central role in both Central Sterile Services Departments (CSSD) and laboratory sterilization workflows, where process consistency, load validation, and traceability are essential. In hospital CSSD environments, autoclaves support the reprocessing of surgical instruments, reusable medical devices, and procedural accessories by providing standardized steam sterilization cycles, controlled pressure and temperature parameters, and reproducible sterilization outcomes across high-throughput operations.

In laboratory settings, medical autoclave sterilizers are critical for maintaining biosafety and experimental integrity. They are widely used for sterilizing glassware, culture media, laboratory instruments, and biohazardous waste prior to disposal. Reliable cycle performance helps minimize cross-contamination, supports regulatory compliance, and ensures a controlled research and diagnostic environment. By supporting both clinical and laboratory sterilization demands, WEGO medical autoclave sterilizers enable healthcare institutions and research facilities to establish unified infection control and biosafety standards across departments.

Comprehensive Support from the WEGO Global Team

When you partner with WEGO, you gain more than trusted medical products – you gain the strength of the WEGO Global Support Team. We are dedicated to helping you maximize performance, ensure reliability, and deliver better outcomes for patients worldwide.

With 37 years of experience, advanced manufacturing, and a worldwide service network, WEGO provides timely assistance, technical guidance, and tailored solutions. Our team works side by side with you to keep operations running smoothly and efficiently.

At WEGO, our commitment starts before the first delivery and grows throughout our journey together. Your success drives our mission, and your trust fuels our progress.

- Access WEGO Expert Support >>

Q1. What is a medical autoclave sterilizer used for?

A: A medical autoclave sterilizer is used to eliminate microorganisms through saturated steam or validated sterilization cycles. It is commonly applied in hospitals, CSSD departments, dental clinics, and laboratories for sterilizing surgical instruments, reusable medical devices, laboratory glassware, and biohazardous materials.

Q2. How does a medical autoclave support CSSD workflows?

A: In CSSD environments, medical autoclave sterilizers enable standardized, repeatable instrument reprocessing. They support validated sterilization cycles, controlled temperature and pressure parameters, and compatibility with cleaning, packaging, and storage workflows, helping reduce variability and improve traceability across high-volume operations.

Q3. What types of materials can be sterilized in a steam autoclave?

A: Steam autoclaves are suitable for heat- and moisture-resistant items such as stainless steel instruments, surgical trays, textiles, laboratory glassware, culture media, and certain medical consumables. Items sensitive to high temperature or humidity typically require low-temperature sterilization methods.

Q4. What is the difference between steam sterilization and low-temperature plasma sterilization?

A: Steam sterilization relies on high temperature and pressure to achieve microbial inactivation, making it ideal for robust medical and laboratory items. Low-temperature plasma sterilization operates at reduced temperatures and is used for heat-sensitive devices, ensuring effective sterilization without damaging delicate materials.

Q5. How do medical autoclaves contribute to infection control?erature sterilization?

A: By providing controlled and validated sterilization cycles, medical autoclave sterilizers reduce the risk of microbial contamination, support consistent instrument reprocessing, and help healthcare facilities maintain standardized infection prevention practices across departments.