Hospitals require a multi-layered approach to infection control, and the sterilization of surgical instruments and medical devices forms its foundation. The methods employed must be both ruthlessly effective and adaptable to a wide range of materials. While several technologies exist, one system serves as the workhorse for the majority of a hospital’s critical needs. The consistent performance of a hospital autoclave machine makes it the most common and relied-upon piece of equipment in the Central Sterile Supply Department (CSSD). Its use of steam under pressure provides a balance of efficiency, reliability, and penetrative power that is difficult to match for heat-stable items.

The Predominance of Steam Sterilization

The primary technology hospitals use for most of their reusable equipment is the steam sterilizer, commonly known as a hospital autoclave machine. This method’s effectiveness comes from its ability to deliver saturated steam at high temperatures, typically between 121°C and 134°C. This steam rapidly transfers thermal energy, coagulating the proteins within all microorganisms, including resistant bacterial spores. The widespread adoption of the hospital autoclave machine is due to its proven efficacy, rapid cycle times, and the fact that steam is a safe and cost-effective sterilant. For all metal surgical instruments, glassware, and certain heat-stable plastics, it remains the first and most logical choice.

Handling Heat-Sensitive Equipment with Low-Temperature Methods

Not every critical or semi-critical item in a hospital can withstand the high heat of steam. The proliferation of sophisticated, delicate devices made from plastics, fiber-optic bundles, and other sensitive materials necessitated the development of alternative, low-temperature sterilization technologies. For these items, hospitals often turn to methods such as Ethylene Oxide (ETO) gas, hydrogen peroxide gas plasma, or vaporized hydrogen peroxide systems. These processes operate at much lower temperatures, often between 40°C and 60°C, allowing for the sterilization of complex items like endoscopes without causing damage. The selection of a low-temperature method is a deliberate choice based on the material composition of the device.

Integrating Systems for a Comprehensive Workflow

A hospital’s sterilization workflow is not a series of isolated actions but an integrated system. The journey of a device begins with point-of-use pre-cleaning at the clinical level, moves to thorough decontamination and manual washing in the CSSD, and is followed by inspection and packaging. Only then is the item routed to the appropriate technology—be it a large-chamber hospital autoclave machine for a standard instrument set or a low-temperature system for a flexible scope. This entire process is supported by rigorous tracking and monitoring, using chemical indicators and biological indicators to validate that sterility has been achieved for every load in every system.

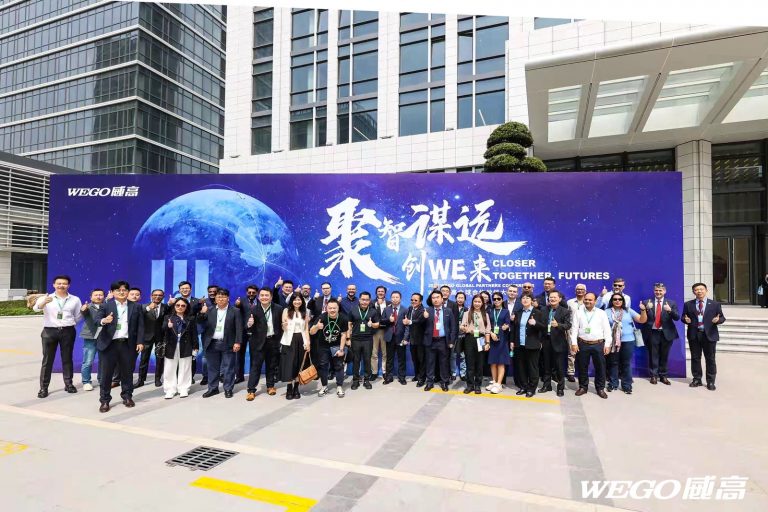

The reliance on a hospital autoclave machine for the bulk of sterilization tasks underscores its irreplaceable role in patient safety. These systems form the backbone of a hospital’s efforts to prevent healthcare-associated infections. At WEGO Medical, we contribute to this vital mission by manufacturing hospital autoclave machines built for durability and consistent performance. We focus on creating equipment that integrates seamlessly into the demanding workflow of a modern CSSD, providing a dependable component within a hospital’s broader infection control strategy.