Healthcare professionals rely on a consistent and efficient method for collecting blood samples. The system used most widely involves a vacuum blood collection tube, a device whose operation is based on straightforward physical principles. This process ensures a pre-measured volume of blood is drawn safely and efficiently, which is critical for accurate diagnostic testing. Understanding how these tubes function can provide insight into their reliability and widespread adoption in clinical settings.

The Role of Pre-Applied Vacuum Pressure

The driving force behind the blood draw is a pre-measured vacuum sealed within the sterile tube during manufacturing. This internal environment has a pressure much lower than the atmosphere. A vacuum blood collection tube remains in this state until the rubber stopper is pierced by the double-ended needle. The pressure difference creates a gradient, and nature seeks to equalize this imbalance. The higher pressure within the patient’s vein pushes blood into the lower-pressure environment of the tube, initiating the flow.

The Interaction of Venous Pressure and Tube Vacuum

Successful filling depends on the patient’s venous pressure being sufficient to overcome the tube’s vacuum. This is why a tourniquet is applied; it increases venous pressure by restricting blood flow, making the vein more prominent and ensuring a strong enough pressure differential. If the venous pressure is too low, the tube may fill slowly or incompletely. The standardized vacuum in each vacuum blood collection tube is calibrated to work in concert with typical human venous pressure, allowing for a consistent and controlled fill volume.

Needle Gauge and Blood Flow Dynamics

The design of the collection needle itself is a factor in the process. The needle’s internal diameter, or gauge, influences the rate of blood flow. A needle with a wider gauge allows for a faster flow rate, which can be important for filling larger tubes efficiently. The system is designed so that once the needle accesses the vein, the vacuum acts immediately, pulling blood through the needle and into the vacuum blood collection tube without requiring manual aspiration. This closed system enhances safety by minimizing blood exposure.

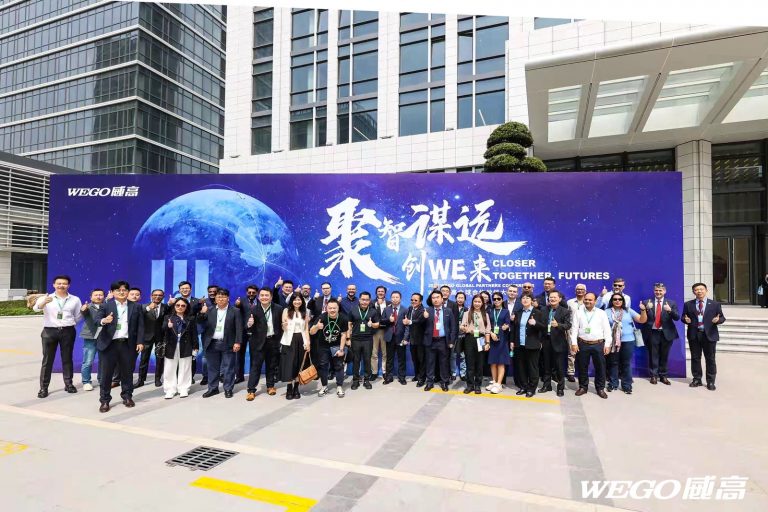

At WEGO Medical, we manufacture these essential devices with a focus on the precision of the vacuum seal and the quality of the tube materials. Our production process ensures that each tube provides the exact vacuum level required for a specific draw volume, supporting healthcare workers in obtaining valid samples for laboratory analysis.

The filling of a vacuum tube is a result of engineered pressure differentials working in harmony with human physiology. This simple yet effective mechanism underscores the importance of device quality and proper technique in phlebotomy. The reliable performance of these tubes makes them a fundamental tool in modern diagnostic medicine, facilitating the first step in countless clinical assessments.