Producing medical consumables requires a specific operational framework that balances precision engineering with scalable production. As a disposable medical products manufacturer, the focus is on creating items that meet strict regulatory standards while fulfilling practical clinical needs. The process involves integrated systems for design, material selection, and quality validation. This approach ensures that each product performs reliably in various medical settings, from routine procedures to complex surgical interventions.

Engineering for Clinical Precision and Reliability

The development phase for any medical consumable prioritizes clinical precision. This means designing products that interface correctly with medical devices and perform consistently under specific conditions. For a disposable medical products manufacturer, this involves detailed prototyping and testing to verify dimensional accuracy, material integrity, and functional performance. The objective is to achieve a design that supports healthcare professionals in delivering care without equipment-related variables affecting the outcome.

Selecting and Validating Raw Materials

A critical part of the manufacturing process is the selection of raw materials. This choice directly influences product safety, compatibility, and performance. Materials must be non-toxic, often sterile, and suitable for their intended use, whether it involves contact with skin or internal tissues. The validation process includes testing for strength, flexibility, and reactivity. Establishing a robust supply chain for these qualified materials is a fundamental task for any producer in this field.

Adapting Products for Cross-Departmental Application

Medical consumables serve a wide range of departments, each with unique requirements. An operating room needs different solutions than a general ward or a laboratory. Therefore, manufacturing must be adaptable, producing a diversified portfolio that addresses specific clinical scenarios. This requires an understanding of various procedural workflows to ensure that the design of a consumable—be it a syringe, a surgical drape, or a specimen container—is fit for its particular environment and use case.

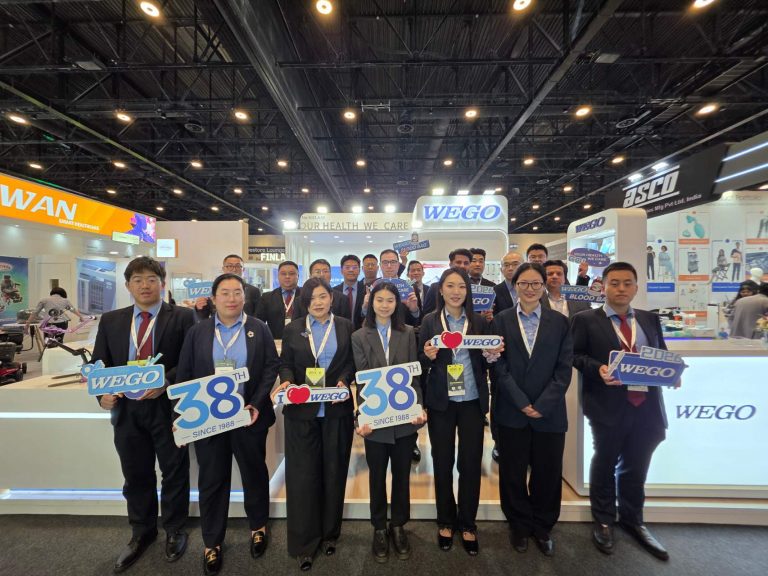

At WEGO Medical, we function as a medical consumables supplier, delivering trusted solutions in medical consumables and disposables. Our products are made for precision and built for every department. This philosophy guides our production, ensuring the items we create meet the demanding needs of modern healthcare facilities. We concentrate on the details of manufacturing to provide reliable tools for clinical teams.

The role of a medical consumables producer is rooted in a disciplined manufacturing and quality assurance process. It is this behind-the-scenes work that guarantees the safety and effectiveness of the products upon which healthcare providers depend. A methodical approach to production forms the basis for trust in the supplier relationship.