The efficacy of a membrane oxygenator, a core component in cardiopulmonary bypass (CPB) systems, depends fundamentally on the advanced materials from which it is constructed. These components must achieve a critical balance: facilitating highly efficient gas exchange while minimizing any adverse reaction with the patient’s blood. The evolution of these devices is, in many ways, a history of material science innovation, moving from simple bubble diffusion to sophisticated, biocompatible membranes that closely mimic the natural lung. Understanding these materials provides insight into the reliability and safety of contemporary oxygenators for CPB.

The Core Gas Exchange Membrane: Hollow Fiber Technology

At the heart of every device is the gas exchange membrane, a component that has been revolutionized by microporous polypropylene hollow fibers. These fibers are incredibly thin, creating a vast surface area within a compact module. Their microporous structure allows for the highly efficient diffusion of oxygen and carbon dioxide between the blood and the ventilating gas. This design is pivotal for the performance of modern oxygenators for CPB, enabling them to support a wide range of patient sizes and clinical demands. The material’s inherent properties help maintain the integrity of the membrane during the procedure, which is crucial for patient safety.

Structural Components and Housing Materials

Surrounding the delicate hollow fibers is a robust structural system designed for durability and seamless integration into the extracorporeal circuit. The outer housing and internal headers are typically manufactured from medical-grade polycarbonate or other tough polymers. These materials are selected for their clarity, allowing clinical teams to visually monitor for air bubbles, and their strength, which ensures the device can withstand the pressures of the bypass circuit. The design must also include patented potting materials that securely bind the thousands of hollow fibers in place, preventing leaks and ensuring blood flows correctly around the fibers rather than through them.

Surface Modifications for Enhanced Biocompatibility

Perhaps the most critical material consideration is the interface with the patient’s blood. When blood contacts a foreign surface, it can trigger coagulation and an inflammatory response. To mitigate this, the internal surfaces of oxygenators, particularly the hollow fibers, are often treated with specialized biocompatible coatings. These surface modifications are applied to reduce thrombogenicity and the subsequent need for excessive anticoagulation. The ongoing development of these coatings represents a significant focus in the field, aiming to make the interaction between blood and the artificial surface as neutral as possible.

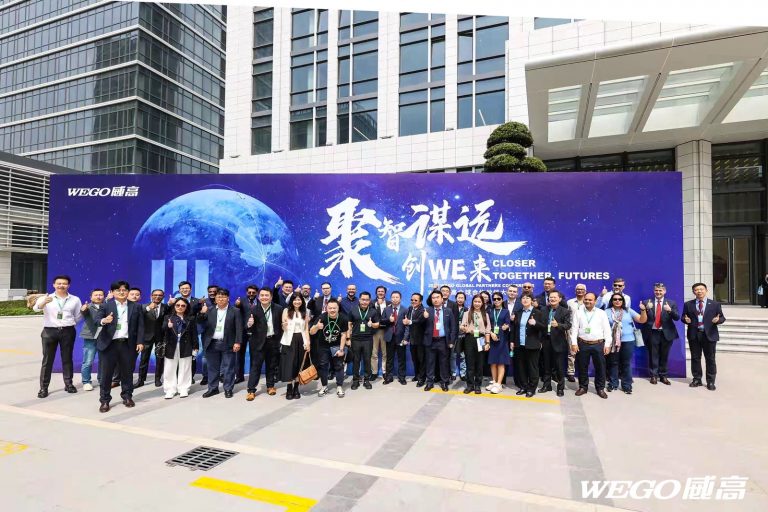

The consistent performance of these devices during complex surgical procedures is a direct result of meticulous material selection and engineering. Each component, from the macro-scale housing to the micro-scale fiber pores, is chosen to fulfill a specific and critical function. At WEGO Medical, we recognize that the reliability of the oxygenators for CPB used in surgery is non-negotiable. Our commitment lies in supporting the medical community through the supply of high-quality components that meet these rigorous material and performance standards, contributing to the safety and success of cardiac care worldwide.